Grades 60-40-18, 65-45-12, 80-55-06, 100-70-03 & 120-90-02

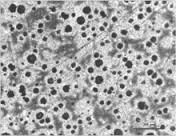

Ductile Iron offers the castability, machinability, and corrosion resistance of gray iron while adding the high strength, ductility, and hardening ability of steel. Our ductile iron castings are well known throughout the industry for high-impact resistance and a high modulus of elasticity and strength, resulting in heavier load capacity with less deflection.

| Specifying Body | Spec. No. | Use | Grade or Class | Min. Tensile PSI | Min. Yield PSI | % Elongation | Heat Treatment | Other Requirements |

|---|---|---|---|---|---|---|---|---|

| ASTM | A395 | Pressure retaining parts for use at elevated temperatures (up to 650ºF) | 60-40-18 | 60000 | 40000 | 18 | Ferritized by annealing | Chemical composition is subordinate to mechanical properties. |

| ASTM | A536 | Maximum shock resistance | 60-40-18 | 60000 | 40000 | 18 | May be annealed | |

| Most widely used grade for normal service | 65-45-12 | 65000 | 45000 | 12 | ||||

| Suitable for flame and induction hardening | 80-55-06 | 80000 | 55000 | 6 | ||||

| Best combination of strength, wear resistance and response to surface hardening | 100-70-03 | 100000 | 70000 | 3 | Usually normalized | |||

| Maximum strength and wear resistance | 120-90-02 | 120000 | 90000 | 2 | Usually quench and tempered | |||

| BHN of Casting | ||||||||

| SAE | J434 | For automotive and allied industries | D-4018 | 170 Max. | May be annealed | The Microstructure shall consist of at least 80% spheroidal graphite conforming to Types I and II and be substantially free of primary cementite. | ||

| D-4512 | 156-217 | |||||||

| D-5506 | 187-255 | |||||||

| D-7003 | 241-302 | May be normalized | ||||||