Class 25,30,35,40 tensile and heat resistant irons.

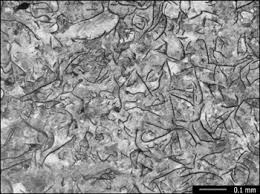

Gray Iron has a dense gray structure and offers excellent machinability. Grades 25, 30, 35 and 40 can fill specific requirements for hardness and wear, and heat treatments can yield even higher mechanical properties. Popular applications for gray iron include diesel and gasoline engine blocks and cylinder liners, and structural machine components where vibration dampening is required.

| Specifying Body | Spec. No. | Use | Grade or Class | Min. Tensile Strength (PSI) | Other Requirements | |

|---|---|---|---|---|---|---|

| ASTM | A126 | Valves, flanges and pipe fittings | A | 21000 | .15% S. Max. .75% P Max | |

| B | 31000 | |||||

| C | 41000 | |||||

| ASTM | A48 | Castings intended for general engineering use where strength is a major consideration | 25 | 25000 |

|

|

| 30 35 |

30000 35000 |

|||||

| 40 | 40000 | |||||

| Brinell Hardness | Micro-structure | |||||

| ASTM SAE |

A159 J431 |

Cast in sand molds for the automobile, truck, tractor, and allied industries | G2500 | 170-229 | Ferritic-Pearlitic | |

| G3000 | 187-241 | Pearlitic | ||||

| G3500 | 207-255 | Pearlitic | ||||

| G4000 | 217-269 | Pearlitic | ||||

| ASTM | A278 | Pressure containing parts for use up to 650ºF | 25 | Castings for intended use above 450ºF should be stress relieved. | ||

| 30 | ||||||

| 35 | ||||||