THE MELTMINDER

A PUBLICATION BY BENTON FOUNDRY, INC.

Web Site: www.bentonfoundry.com

O

ur last newsletter covered Outside Sales. Phase 4 is focused on our Quality Department. The Quality Department consists of Chad Davis, Ana Ponce, Randy Kadtke, Xenia Ponce, Cody Snyder, Thomas Zelinka, Isabella Kubasek, Jackie Showers, Morgan Lancenese, Eric Malcein and Steve Lappan. There are a lot of “moving parts” to the Quality Department and everyone has their certain job responsibilities. There is a variety of testing, sampling, calibrating, inspecting and auditing.

Chad Davis has a Mechanical Engineering degree from Penn State University. Chad is a self-described motor-head. He is married with a son and has been employed at Benton Foundry since 2014. His wife is a teacher in the East Lycoming School District. Chad is known for his methodical, even-keeled and scientific approach in resolving foundry quality issues. Chad had the chance to study under a true foundry guru Matt Lobos, a Penn State Foundry Engineering graduate. Chad took over as Head Quality Manager last summer upon Matt’s retirement after being at Benton for 21 years.

Chad Davis has a Mechanical Engineering degree from Penn State University. Chad is a self-described motor-head. He is married with a son and has been employed at Benton Foundry since 2014. His wife is a teacher in the East Lycoming School District. Chad is known for his methodical, even-keeled and scientific approach in resolving foundry quality issues. Chad had the chance to study under a true foundry guru Matt Lobos, a Penn State Foundry Engineering graduate. Chad took over as Head Quality Manager last summer upon Matt’s retirement after being at Benton for 21 years.

Ana Ponce is a degreed Civil Engineer who has been at Benton Foundry since 2019. She has worked in multiple departments before coming into the Quality Department in January 2020. Ana had a big 2025 in buying a new house and having her second son. Her husband has been employed at the Wise Potato Chip factory for many years. Ana has been helpful in upgrading photos to the Benton quality system. She also has been instrumental in translating Benton work procedures into Spanish.

Ana Ponce is a degreed Civil Engineer who has been at Benton Foundry since 2019. She has worked in multiple departments before coming into the Quality Department in January 2020. Ana had a big 2025 in buying a new house and having her second son. Her husband has been employed at the Wise Potato Chip factory for many years. Ana has been helpful in upgrading photos to the Benton quality system. She also has been instrumental in translating Benton work procedures into Spanish.

Randy Kadtke is a soon-to-retire quality person of Benton Foundry. Randy came to us when Techneglas of Pittston closed its large manufacturing facility. Randy was very instrumental in Benton instituting its program of scanning patterns, core boxes and castings. He recently led the effort to the next generation of scanners that could help in reverse engineering castings. Randy was a favorite of the accounts he was assigned. We wish Randy, his wife and extended family a long and happy retirement. Randy started with Benton in 2011.

Randy Kadtke is a soon-to-retire quality person of Benton Foundry. Randy came to us when Techneglas of Pittston closed its large manufacturing facility. Randy was very instrumental in Benton instituting its program of scanning patterns, core boxes and castings. He recently led the effort to the next generation of scanners that could help in reverse engineering castings. Randy was a favorite of the accounts he was assigned. We wish Randy, his wife and extended family a long and happy retirement. Randy started with Benton in 2011.

Xenia Ponce has a five-year accounting degree and had been targeted to work in the office. Xenia is renown for attacking and understanding any assignment. When an opening came up in quality and as is evident in the foundry industry, there was a shortage of applicants, Xenia rose to the occasion and has quietly excelled at all assignments. Her most recent has been doing all the scanning on the new Romer Arm made by Hexagon. Hexagon is one of the two leading brands in the industry. Xenia started working on the shop floor in 2021.

Xenia Ponce has a five-year accounting degree and had been targeted to work in the office. Xenia is renown for attacking and understanding any assignment. When an opening came up in quality and as is evident in the foundry industry, there was a shortage of applicants, Xenia rose to the occasion and has quietly excelled at all assignments. Her most recent has been doing all the scanning on the new Romer Arm made by Hexagon. Hexagon is one of the two leading brands in the industry. Xenia started working on the shop floor in 2021.

Cody Snyder has his Masters Degree in Metallurgy from Penn State University. There he studied iron under Professor Robinson. Cody has been with Benton Foundry since 2019. He is a product of Benton’s 40+ year relationship with the Penn State University foundry program. Cody runs the Quality Roundtable which is known for its robust quality conversations and resultant projects. He is a very responsive person to the point you would think he and Quality Manager Chad Davis were brothers from another mother.

Cody Snyder has his Masters Degree in Metallurgy from Penn State University. There he studied iron under Professor Robinson. Cody has been with Benton Foundry since 2019. He is a product of Benton’s 40+ year relationship with the Penn State University foundry program. Cody runs the Quality Roundtable which is known for its robust quality conversations and resultant projects. He is a very responsive person to the point you would think he and Quality Manager Chad Davis were brothers from another mother.

Tom Zelinka came to Benton as the newbie in June of 2025. He is the replacement for Randy Kadtke who is retiring in February of 2026. Tom has been doing a hand’s-on rotation of the various production jobs on the shop floor. In addition he has attended ASK Chemical’s core workshop and also the recent Penn State Foundry seminar sponsored by the Federal Governments desire to increase the technical level of its foundry workers. In addition he has completed over 30 online AFS foundry courses. His work experience has been very “Targeted” so far. Tom is a Wilkes University graduate in Electrical Engineering. Tom scored near record numbers on his Benton testing. Tom had Quality Engineer related jobs in the ten years from graduation until his start at Benton Foundry. Tom and his wife are expecting their first child in 2026.

Tom Zelinka came to Benton as the newbie in June of 2025. He is the replacement for Randy Kadtke who is retiring in February of 2026. Tom has been doing a hand’s-on rotation of the various production jobs on the shop floor. In addition he has attended ASK Chemical’s core workshop and also the recent Penn State Foundry seminar sponsored by the Federal Governments desire to increase the technical level of its foundry workers. In addition he has completed over 30 online AFS foundry courses. His work experience has been very “Targeted” so far. Tom is a Wilkes University graduate in Electrical Engineering. Tom scored near record numbers on his Benton testing. Tom had Quality Engineer related jobs in the ten years from graduation until his start at Benton Foundry. Tom and his wife are expecting their first child in 2026.

Eric Malcein is the ISO Administrator for Benton Foundry. As such, he gets into every department to Audit the Benton Foundry extensive quality process. In addition to these duties, he has been actively in the Material Resolution process of Benton Foundry where he reviews new products for inclusion into the process. This has expanded his foundry depth considerably. Eric was one of the individuals who benefited, as did Benton Foundry, by attending Pennsylvania College of Technology program. He worked part-time and went to College in Williamsport, PA full-time and was fully paid for this process. Eric graduated with a degree in Advanced Manufacturing Technology. He was the 2020 Alfred Hauver Memorial Award recipient. In addition he had a 4.0 GPA throughout his college career; a real feat considering in addition to full-time school, he was working 20+hours per week. The near $50,000 investment was money well spent.

Eric Malcein is the ISO Administrator for Benton Foundry. As such, he gets into every department to Audit the Benton Foundry extensive quality process. In addition to these duties, he has been actively in the Material Resolution process of Benton Foundry where he reviews new products for inclusion into the process. This has expanded his foundry depth considerably. Eric was one of the individuals who benefited, as did Benton Foundry, by attending Pennsylvania College of Technology program. He worked part-time and went to College in Williamsport, PA full-time and was fully paid for this process. Eric graduated with a degree in Advanced Manufacturing Technology. He was the 2020 Alfred Hauver Memorial Award recipient. In addition he had a 4.0 GPA throughout his college career; a real feat considering in addition to full-time school, he was working 20+hours per week. The near $50,000 investment was money well spent.

The next phase will cover the Core Room.

C

ongratulations to Timmy Schechterly (below), Benton Foundry’s 1st shift Employee of the Quarter. Timmy works in Maintenance and has been employed at the Foundry since 2019. Timmy lives in Hunlock Creek and in his spare time he enjoys being outdoors. He likes to fish on the Susquehanna River, ride ATVs and dirt bikes, watch movies and work in the garage. Congratulations Timmy!

Amazing Job!

C

ongratulations to Stan Shuleski (below), Benton Foundry’s 2nd shift Employee of the Quarter. Stan has been employed at the Foundry since 2022. He currently works in the Grinding Department and is training to be an Assistant Supervisor. Stan lives in Bloomsburg and he enjoys cooking, driving and spending time with his daughter Sophia when he isn’t working. Congratulations Stan!

Awesome Job!

Other nominees for Employee of the Quarter included: Geremias Osario, Tom Foust, Justin Boyer, Amanda Hartman, Gene Ryman, Elissa Romberger, Debbie Clocker, Gilberth Aleman, Xenia Ponce, Nelson Lemus, Jose Jesus Martinez, Nuria Artero and Edwin Ramirez.

C

ongratulations to Ryan Keeler (below), Benton Foundry’s 1st shift Employee of the Year. Ryan works in the Melt Department as an Assistant Supervisor. He has worked at the foundry since January 2020. Ryan previously worked in the core room as a core machine operator. He lives in Benton with his wife Miranda and their two children. Ryan enjoys hunting, fishing and spending time with is family in his spare time.

Thank You and Great Job Ryan!

C

ongratulations to Andy Spencer (below), Benton Foundry’s 2nd shift Employee of the Year. Andy works in the Core Room as an Assistant Supervisor. He has worked at the foundry for 25 years. Andy has held many positions in various departments over the years. He lives in Shickshinny with his wife Amy. He has three children and 1 grandson and he enjoys fishing, NASCAR and spending time with his family when he isn’t working.

Thank You and Great Job Andy!

W

e just replaced the main trunk of the ductwork for CLL10 which is the dust collector serving the furnaces and mullers. That system was installed in 2010 along with “the collector on the hill” and smaller portions of it were replaced in 2017 and 2019. The system is unique in that it doesn’t battle abrasion like the other collection systems for the sand system or grinding room, but rather corrosion.

Based on the projected longevity of the 10-gauge galvanized steel used originally, we decided to make the new version out of 316 stainless steel to resist the heat of the furnaces and the moisture from the mullers. This upgrade is now expected to last quite a long time. An estimated 70% of the ductwork associated with that collector is now stainless steel with all of the largest parts converted.

Based on the projected longevity of the 10-gauge galvanized steel used originally, we decided to make the new version out of 316 stainless steel to resist the heat of the furnaces and the moisture from the mullers. This upgrade is now expected to last quite a long time. An estimated 70% of the ductwork associated with that collector is now stainless steel with all of the largest parts converted.

The scope of work was replacing nearly 400 feet of mostly 60-inch (5-foot) diameter piping located on the roof above the Melt Department. The work was completed by Penn American over the course of about 4 days with the help of one of the largest cranes in the area to handle the reach needed.

D

uring the 2nd half of 2025, Benton Foundry’s community outreach included the following activities:

- Navy Football Brotherhood, Inc. in honor of TJ Costello, Foundry Manager at Charlotte Pipe – Donor

- Foundry Educational Foundation (FEF) – Donor

- Sullivan County High School Sullivan County High School – Donor

- Slaughterhouse Wrestling – Donor

- Northern Columbia Community & Cultural Center (N4Cs) – Donor

- Benton Winterfest – Donor

- Scranton Preparatory School – Donor

- Camp Victory – Donor

- Benton Varsity Cheerleaders – Donor

- CCHS Theatre – Donor

- Non-Ferrous Founder’s Society (NFFS) in honor of Lou Iannettoni of Syracuse NY – Donor

I

f you’ve ever had to replace your car keys through your dealership, you know how expensive that can be. That’s why AAA has partnered with Car Keys Express. Car Keys Express offers original equipment manufacturer fobs (known as smart keys) and keys as well as its own premium aftermarket keys at savings of 40% to 70% compared to dealer prices. And AAA members save an additional 20% on eligible products. If you have an existing key (even fobs usually have an emergency key tucked inside), there are two ways to get service: make a key online, have it shipped to you and then pair it with the supplied EZ Installer, or shop online for your key and use van service for on-site installation. Lost your only key or fob? No worries. Car Keys Express will come to you and create a new key. To get your car key or fob at a fraction of the dealer cost, go to AAA.com/CarKeys.

~ AAA.com The Extra Mile Fall/Winter 2025

Back Row: Jim Lamoreaux (Navy), Paul Simko (Army), Bob Houser (Army) and Kenny O’Brecht (Army)

L

eading people think of the “Mag” seven when it comes to top performing stocks. The number 1 may surprise you. This from Kiplinger Personal Finance. To make their top-10 list, a stock had to return more than 30,000%. Some stars of the 21st century didn’t make the cut simply because they haven’t shone quite long enough. Netflix is one. The DVD shipper-turned-streamer debuted its stock in May 2002, a little late for this list. But since its initial public offering, Netflix has returned more than 100,000%. Still, our top 10 is loaded with power hitters. Here is the #1.

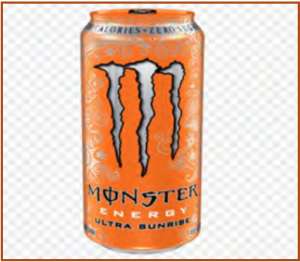

1. Monster Beverage. 25-year cumulative total return 155,103%.

1. Monster Beverage. 25-year cumulative total return 155,103%.

A monster indeed. The company was known as Hansen Natural, having started in the 1930s as a seller of juices. By 2012, shareholders voted to change the company’s name to Monster, reflecting the line of energy drinks that today make up more than 90% of revenue.

The sellers of these drinks, which contain more caffeine and sugar than traditional soft drinks, market them as boosting physical and mental energy. Monster is now the biggest player in a global market estimated at $90 billion in sales, with a 46% share in North American, according to Morningstar analyst Dan Su.

The key to dominance was a 2015 deal with Coca-Cola that saw the beverage giant distribute Monster products worldwide in exchange for a stake in the company that stands at about 20% today.

The energy-drink category is still growing faster than most beverages, and there’s a new offshoot: performance beverages, or “better-for-you” drinks, which are often sugar-free and more narrowly target athletes and health-conscious consumers. Andrew Strelzik, of BMO Capital Markets, who has a “hold” rating on the stock, says Monster has lost share in the category recently.

Nonetheless, Monster shares have gained more than 20% since sales growth picked up in the fourth quarter. That has left a number of analysts saying the market is now too confident about the firm’s prospects. According to S&P Global, just 14 of 26 analysts who follow the stock have a “buy” rating on Monster; three give it the rare “sell.”

The rest of the top ten are as follows:

- NVIDIA

- Apple

- Booking Holdings

- Tractor Supply Company

- Texas Pacific Land

- Old Dominion Freight Line

- Deckers Outdoor

- Tyler Technologies

- Comfort Systems USA

~Kiplinger Personal Finance

I

t may not be age that is making your hair thin or fall out, but rather what you are eating and drinking. New research shows certain foods contribute to hair loss, and others help with hair growth. Sugar-sweetened beverages and alcoholic drinks are associated with a higher risk of hair loss, according to research published in Nutrition and Health, which analyzed 17 studies on diet and hair.

“When we consume high amounts of sugar, we get an insulin spike that promotes inflammation and can distort the natural hair growth cycles,” explains Laura Acosta, a registered dietitian and associate professor of Food Science and Human Nutrition at the University of Florida. “With alcohol, it’s not that it necessarily directly causes hair shedding itself, but it does contribute to nutrient deficiency, nutrient malabsorption, liver stress, poor sleep, and systemic inflammation — all of which can wreak havoc on hair growth.”

Not consuming enough protein also can lead to hair loss. Acosta says a person needs to take in half a gram of protein per pound of body weight each day (A 200lb person=100 grams of protein). “We tend to be more protein-deficient than we think,” said Dr. Jila Senemar, a Miami menopause specialist who says hair shedding, hormones, and diet are all interrelated.

Foods that can help with healthy hair and hair growth include soy-based nourishment like edamame or tofu, and cruciferous veggies like broccoli or cauliflower, which can reduce the risk of hair loss. Nutritionists believe this is likely due to the antioxidant and anti-inflammatory properties of their phytochemicals, such as isoflavones and carotenoids. Additionally, persimmon leaf has been studied and found to be linked to improvements in both hair density and thickness. Persimmon leaf contains antioxidants like quercetin that improve blood flow to the scalp. You can drink it in tea or take an oral supplement.

While most studies in this new review primarily included women, one study involving 76 men with male pattern baldness found greater hair growth in a group that consumed 400 mg of pumpkin seed oil for 24 weeks compared to a placebo group. Researchers believe the reason for the hair growth may be hormonal — pumpkin seed oil may decrease dihydrotestosterone (DHT), a hormone known to affect hair follicles and cause hair thinning.

When it comes to supplements, Vitamin D has been the most studied. At least five studies analyzed in this review found that higher vitamin D levels may be protective against hair loss. Acosta said 2,000 international units (IUs) would be a good dose to aim for, noting there is risk for toxicity if someone takes too much.

When it comes to supplements, Vitamin D has been the most studied. At least five studies analyzed in this review found that higher vitamin D levels may be protective against hair loss. Acosta said 2,000 international units (IUs) would be a good dose to aim for, noting there is risk for toxicity if someone takes too much.

Another supplement to consider is iron. One study showed that iron supplementation (in the form of 100-milligram tablets) improved hair growth in women. Senemar, the Miami doctor, said if someone is iron-deficient and wants to take supplements, she suggests taking them with vitamin C, which can help increase iron absorption. She points out that certain foods are good sources of iron, including spinach, lentils and almonds.

Acosta recommends having your iron levels tested along with your zinc and biotin (Vitamin B7) levels because deficiencies can cause hair loss or thinning. Adults need 30 micrograms of biotin daily. It can be found in foods like meats, eggs, fish, seeds, nuts and vegetables like sweet potatoes. “If you’re not biotin deficient, though, taking biotin supplements is unlikely to help your hair,” Acosta said. Recently, research has been focused on collagen for hair growth. “There is some exciting research going on around collagen supplements that a few years ago I probably would have dismissed, but now it really has my attention,” she said.

For the newly published review, researchers scoured three big scientific databases — PubMed, Web of Science, and Scopus — using keywords like “dietary intake,” “nutritional status,” and “hair growth.” In total, the studies involved 613,320 individuals, mostly females, ranging in age from 7 to 77 years old. These were observational studies, meaning that we see associations, but we can’t necessarily prove causation from these types of studies,” Acosta explained.

~ Cindy Krischer Goodman / South Florida Sun Sentinel

T

he IRS will generally no longer send out paper refund checks after Sept 30, 2025. President Trump signed an executive order mandating that the Department of Treasury get rid of paper checks for recipients of benefits, tax refunds and other payments. Including in the reasons given for ending paper checks are the cost, inefficiencies and delays; mail theft and fraud risk; and lost and undeliverable payments. All federal departments and agencies, including the IRS, will use electronic funds transfers, direct deposit, prepaid card accounts or other digital payment options. There are limited exceptions, including one that applies to individuals who don’t otherwise have access to banking services or electronic payment systems. The IRS is also phasing out acceptance of paper checks as tax payments from taxpayers.

he IRS will generally no longer send out paper refund checks after Sept 30, 2025. President Trump signed an executive order mandating that the Department of Treasury get rid of paper checks for recipients of benefits, tax refunds and other payments. Including in the reasons given for ending paper checks are the cost, inefficiencies and delays; mail theft and fraud risk; and lost and undeliverable payments. All federal departments and agencies, including the IRS, will use electronic funds transfers, direct deposit, prepaid card accounts or other digital payment options. There are limited exceptions, including one that applies to individuals who don’t otherwise have access to banking services or electronic payment systems. The IRS is also phasing out acceptance of paper checks as tax payments from taxpayers.

~ Kiplinger Personal Finance Adviser – May 2025

Good Job to Stephanie Selman-Guffey and Cohan Nafus for their eagerness to learn and willingness to take on more responsibilities as they train in Maintenance.

Awesome Job to Edwin Ramirez for his skills on the Foxalls and his willingness to stay and help out in other departments when needed

Thanks to Cassandra Shoemaker for cleaning the mullers and her willingness to help out in other departments.

Good Job to Sheila Vansock for completing Metal-Sand Science (Fundamentals) Training Program.

Awesome Job to to Steven Bochenko, Cohan Nafus and Gabriel Keller for completion of the Inductotherm Safety and Maintenance Training.

Good Job to Cohan Nafus, Stephanie Selman-Guffey, Kurtis Hunsinger and Steven Bochenko for completing Arc Flash Training.

Great Job to Tom Zelinka for learning the ropes in the Quality Department.

Kudos to Kyle Hall for taking on additional responsibilities in the Quality Department.

Awesome Job to Jose Lopez on learning furnace operations.

Congratulations to the Foxall operators and programmers on solid uptime numbers this past quarter.

Thanks to several production employees that routinely help with maintenance.

Great Job to Annette Brown for all of her extra effort during the interim period in Human Recourses.

1

out of 10 Pennsylvania residents have unclaimed money that the Pennsylvania Treasury Bureau is trying to return to rightful owners with an average claim of $1,600. A message from Treasurer Stacy Garrity: “Treasury receives hundreds of millions of dollars in unclaimed property every year, often because of something as simple as a misspelled name or an out-of-date address. But let’s be clear: this is YOUR money we’re talking about, and I want to return it to you.” It’s easy and won’t cost you a thing, just follow these 3 easy steps:

- Go to patreasury.gov/unclaimed-property.com

- Click Search Now and enter your name (“Last name only” makes searching easier)

- If you find property, follow the steps to file your claim. (only takes a few minutes)

No matter how big or small the amount, it’s your money waiting for you to claim it! Why not take a few minutes and see if you have any unclaimed property waiting for you. Value Returned from 1/1/21 to 9/30/25 is $913 Million.

~ patreasury.gov

D

ebbie Clocker retired on December 31, 2025 after nearly 26 years. She has worked in Accounts Receivable her entire career at Benton Foundry. Debbie is not one to sugarcoat her feelings. She lets you know her thoughts, whether good or bad, no matter who you are, which always made the days interesting.

Debbie lives in the Benton area with her husband Rich. Together they have a son and a daughter. They also have 3 grandchildren.

Debbie has a great sense of style and a pair of shoes for each outfit. In her younger years, Debbie liked to sew and has been known to make her own clothes. She enjoys going for walks and spending time with her grandchildren. We wish Debbie a long, happy and healthy retirement.

Best Wishes and Congratulations Debbie!

O

n November 11, 2025 Benton Foundry’s Kyle Hall, Olin Covington, Kevin Trychta and Sheila Vansock visited Asbury Carbons in Sunbury, PA. Coincidentally, Benton’s truck was there for a pickup at the same time offering a rather unique opportunity for an impromptu photo shoot.

Asbury Carbons is a major supplier of natural and synthetic graphite, cokes, coals, and all carbon products, as well as a variety of raw materials used around the world.

In the picture is Kyle, Olin, Kevin and Sheila (yellow hats) along with Sheldon Hurst (Plant Manager at Asbury) and Matt Barr (Quality Manager at Asbury).

Elissa Romberger

Jim Tumolo

Glenda Chavez

Noel Flores

Scott Vandine

Randy Kadtke

Boane Berg

Shawn Frey

Fred Hittle

Joseling Martinez

Gene Ryman

Mark Coleman

Marty Pelas

Kenny O’Brecht

Colton Young

Ceidy Hernandez

Matt Shultz

Mike Shultz

Eric Barnes

Harry Fry

Jose A. Mendoza

Mike Modla

Francisco Mendoza

Jeff Jones

Kris Young

Olin Covington

Lynn Sheatler

Joe Timko

Nate Foust

John Andrews

Tom Foust

Greg Vandine

Ryan Keeler

Tim Shepherd

David Straub, Sr.

Trevor Kinsey

Olivia Schechterly

Chris Madl

Josh Vanderhoff

Stan Bohenek

Katherine Miron

Gerson Urbina

Francisco Rocha

Bob Little

Sindy Rodriguez

Della Norton

Annette Brown

Justin Boyer

Andy Spencer

Mike Schumacher

Nuria Artero

Melida Vasquez

Brenda Mendez

Carlos Tellez

When did the New Year’s Eve Ball first drop in Times Square?

Answer will be in 1st Quarter 2026.

What root vegetable was traditionally used to carve Jack-O-Lanterns?

Turnip

Congratulations to the following personnel for their 4th Quarter 2025 performance.

| Sergio Aguilera | Highest Foxall Uptime |

| Jacqueline Artero | Highest Grinding Efficiency |

| David Straub | Highest Molding Efficiency |

| David Straub | Highest Molds per Hour |

| Ed Evans | Lowest Molding Scrap Rate |

| Nuria Artero | Highest Core Production Efficiency |

| Myriam Mayorga | Highest Core Assembly Efficiency |

K

udos to our Lab for once again scoring well in the Iron Casting Research Institute’s (ICRI) round 55 Spectrometer Proficiency Testing. Benton Foundry’s Lab once again showed no statistically significant differences for repeatability and reproducibility. This testing measures repeatability and consistency between various technicians within a lab and reproducibility and consistency between different labs. Our Lab has continually been recognized for consistently high performance in these exercises. Thanks to Bill Simback, Jackie Showers, Cody Snyder, Xenia Ponce, Isabella Kubasek and Morgan Lancenese.

B

enton Foundry’s Tim Brown, PFA President, Steve DeFrank, Head of Pa Utility Commission and Spring City’s Alan Brink, PFA Vice President attend annual PFA meeting.

DeFrank was the featured speaker for the 50 foundry people in attendance. DeFrank was probed on the AI centers and does PA have enough electricity to serve all the residents needs? DeFrank said it was problematic at present. Also there was a discussion about how much the transmission portion in PA had gone up in the past several years and was that going to continue? The real question is why are these new data centers not paying for all the new electrical plants needed?

I

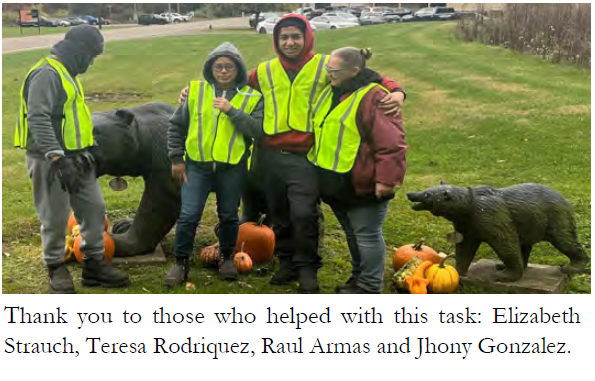

n October, the semiannual fall Adopt-A-Highway litter pickup was completed by Benton Foundry employees. Final count was 13 bags with additional miscellaneous debris.

“The Wisdom Well”

Don’t judge each day by the harvest you reap, but by the seeds that you plant.

~ Robert Louis Stevenson