THE MELTMINDER

A PUBLICATION BY BENTON FOUNDRY, INC.

Web Site: www.bentonfoundry.com

BF History Part 5:

In our last article we saw how A.J. Hall and Elmer Kime took a bankrupt Hallstead Foundry in 1929 and through hard work and perseverance developed it into a top competitor in the iron industry.

By 1958 Hallstead Foundry had gained an enviable reputation of delivering high quality castings to their customers in a timely and efficient manner. The demand became such that other avenues had to be pursued in order to fulfill customers needs. Both Mr. Hall and Mr. Kime knew that the business needed to expand and discussed buying another foundry. They looked for a foundry that was relatively close in location for control purposes and one that could handle the work overflow as business increased.

It came to their attention the Harrington Foundry, that was in a declining posture, could possibly fit their needs. After a few negotiating sessions. Stanley, Roy and Alfred Harrington met with A.J. Hall and Elmer Kime on June 11, 1958 at about 7:00 p.m. and closed the deal for 25 thousand dollars.

The Harrington brothers continued to work at the now Benton Foundry in various capacities, which made for a very smooth transition period for the new ownership. Mostly smaller squeezer work was delegated to Benton Foundry during the early start-up years.

In 1960 a used Cupola (the same cupola that was running until 1996) was purchased from Manlius Foundry in New York and put into operation at Benton Foundry. It was built in the 1940’s. At the time, there were no large power lines coming into the foundry and our power source was from 3 large diesel generators. Larger 440 power lines came out to us in 1970 when our pollution control system was installed.

In 1972 the first BP automatic molding machine was a welcome addition to Benton Foundry as more work was being placed here from Hallstead. Other equipment was sent down as needed from the parent foundry which made most of Benton Foundry’s equipment “secondhand.”

Also, in 1965-1972 building additions were made in the grinding area, core room and office spaces as our output continued to increase. It was apparent to everyone that there was definitely great potential for this small foundry out in the country.

During the years 1958-1974 there were a number of management personnel involved in the operations of both Hallstead and Benton Foundries. They commuted to Benton from Hallstead on a daily basis. In addition to his primary duties, as sales manager of both foundries, Fritz Hall assisted in the management of the Benton Foundry from 1960-1963. At that time, he had no idea what was to take place some 15 years later.

The major operational responsibilities at Benton Foundry, in the absence of the Hallstead managers, fell on the shoulders of Stanley Temple and Harry Thomas, both longtime Benton Foundry employees from the Harrington transition.

In early 1974 the family members of A.J. Hall and Elmer Kime that were involved in the operational activities of both Hallstead and Benton Foundries were as follows – from the Hall family there were: A.J. Hall (co-owner), Raymond (Butch) Hall, Alfred B. (Fritz) Hall and Dave Adams (son-in-law of A.J. Hall). From the Kime family: Elmer Kime (co-owner), Robert Kime, Charles Kime, Dave Kime and Jim Alexander (son-in-law of Elmer Kime).

In January 1974 A.J. Hall was diagnosed with terminal cancer and passed away in March of that year. The death of A.J. Hall, was a significant event for the future of both Hallstead and Benton Foundries. Mr. Hall served as the President of both facilities for many years, as these facilities expanded.

In our next newsletter, we will cover what happened after the passing of A.J. Hall that led to the new ownership of Benton Foundry by 1975.

T

he average American business closes shop after about 21 years. (Of course, the back half of the bell curve never reaches drinking age.) Some businesses, though, last longer – a lot longer. Take Kong Gumi, a Japanese construction company founded in 578 A.D., or Santa Maria Novella, an Italian pharmacy that’s been perfuming the elite since Michelangelo was decorating ceilings. Here are some longevity lessons from businesses that know something about survival.

Angela Serratore, The Longevity Issue – December 2023

Brooks Brothers, Est. 1818

Lesson: Change – but not too much

Founded as a small clothing manufacturer and shop in Lower Manhattan, Brooks Brothers has been supplying starched shirts and blue blazers for more than 200 years. When Ken Ohashi took over the company in 2020, it was a strange time for a brand that depends on more formal wear. Brooks Brothers pivoted and casual wear such as oversized striped rugby shirts now account for 40% of sales. “Our core customer loves our sweatpants,” Ohashi says, “because you can get them monogrammed.”

Santa Maria Novella, Est. 1612 (Pharmacy from 1542)

Lesson: Signature products are signature products for a reason.

For Gian Luca Perris, chief executive officer and “nose” of Officina Profumo-Farmaceutica di Santa Maria Novella, the brand’s most enduring fragrance is inextricably linked to its most famous patron Catherine de’ Medici. Acqua della Regina with top notes of petitgrain and base of musk, is still one of Santa Maria Novella’s bestselling products, a chance for today’s shoppers to capture a little bit of long-ago glamour and romance.

For Gian Luca Perris, chief executive officer and “nose” of Officina Profumo-Farmaceutica di Santa Maria Novella, the brand’s most enduring fragrance is inextricably linked to its most famous patron Catherine de’ Medici. Acqua della Regina with top notes of petitgrain and base of musk, is still one of Santa Maria Novella’s bestselling products, a chance for today’s shoppers to capture a little bit of long-ago glamour and romance.

Consolidated Edison, Est. 1823 (As The New York Gas Light Co.)

Lesson: Location, location, location

ConEd, energy provider to New York City and many of its surrounding counties, is the oldest continuously operating company listed on the New York Stock Exchange. It even predates Thomas Edison himself – when he was born in 1847, the company that would bear his name was known as the New York Gas Light Co. By the mid-1920s, ConEd wiped out the competition, becoming the sole source of electric light in a city known for it.

ConEd, energy provider to New York City and many of its surrounding counties, is the oldest continuously operating company listed on the New York Stock Exchange. It even predates Thomas Edison himself – when he was born in 1847, the company that would bear his name was known as the New York Gas Light Co. By the mid-1920s, ConEd wiped out the competition, becoming the sole source of electric light in a city known for it.

The Olde Bell, Est. 1135

Lesson: Furniture changes, but service shouldn’t

Once upon a time, you might pull into the Olde Bell hotel, about 35 miles outside London, expecting to get a pint of ale and a hunk of bread to dip in your stew before you fell asleep on a horsehair bed. Since then, the Olde Bell has expanded to include more guest quarters and a nuclear fallout shelter-turned-wine cellar, but the idea that every traveler deserves a place to rest and a pint of ale remains the same, says sales manager Debi Hayes – “except we’ve got comfier mattresses now!”

Kongo Gumi Co., Est. 578

Lesson: Find a niche and don’t let go

Until it became a subsidiary of Takamatsu Construction Group in 2006, Kongo Gumi was the world’s oldest continuously operating company. Even now it still does things the really, really old-fashioned way. Its specialty is the restoration of Buddhist temples and other historic buildings, where workers were sometimes set against one another, competing to see which craftsperson demonstrated the most skill in working with the timber and clay traditionally used to build temples.

St. Peter Stiftskulinarium, Est. C. 803

Lesson: Don’t be afraid to mix it up

St. Peter Stiftskulinarium – long known for its wine collection – has been delighting diners in Salzburg, Austria, for more than 1,200 years. Nora Wunderwald, a spokesperson for St. Peter, says patrons such as Mozart, Faust and Karl Lagerfeld would go for the food as well as drink. The restaurant makes it a point to diversify the menu. Recent offerings have included confit fillet of char, artichoke Wellington and an innovation Charlemagne and his compatriots would surely have marveled at: brunch.

So we compared Benton Foundry, Inc.

Est. 1866 (Harrington Plow/Harrington Foundry)

Lesson: Adapt to the needs around you

From the first plow, to sled shoes for the logging/tanning industries, to helping with the war efforts, to growing through the industrial revolution, then the hanging on through the severe downsizing of the industry over several decades, to making castings for today’s companies and the world, the products have changed over the last 158 years, along with the equipment, but we are still melting and pouring metal for the world around us.

From the first plow, to sled shoes for the logging/tanning industries, to helping with the war efforts, to growing through the industrial revolution, then the hanging on through the severe downsizing of the industry over several decades, to making castings for today’s companies and the world, the products have changed over the last 158 years, along with the equipment, but we are still melting and pouring metal for the world around us.

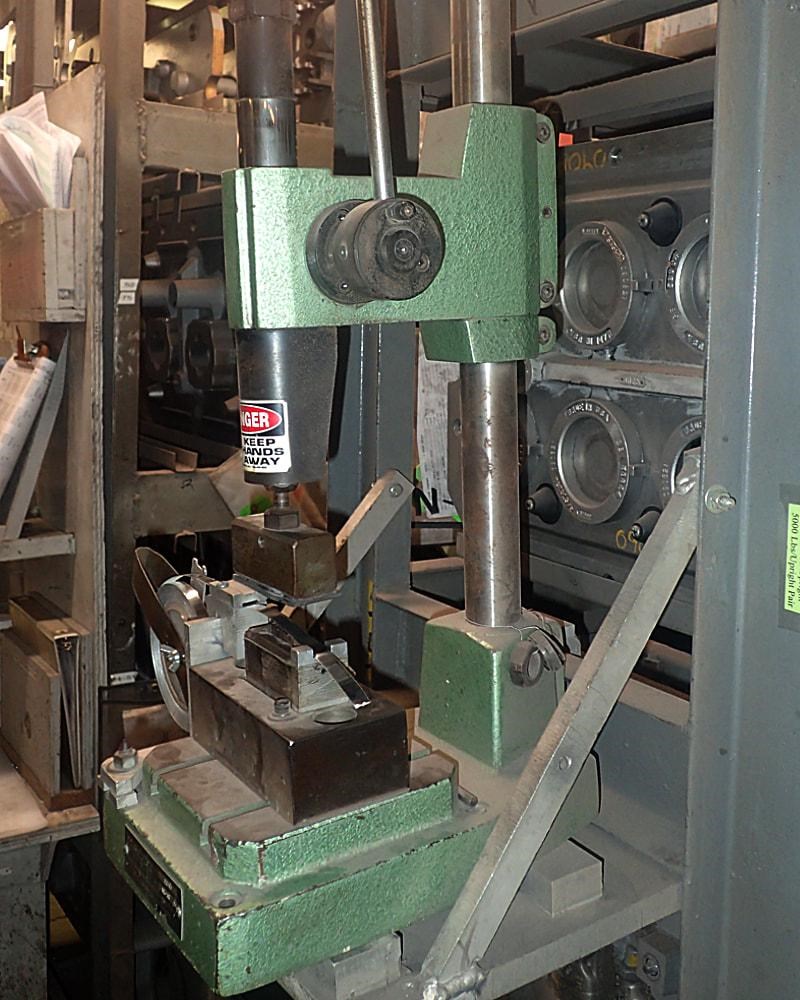

B

ack in 2002 Benton Foundry was presented with a unique problem that needed to be solved. This involved how we date code our pattern impressions for traceability. Laurie Barcaskey, at Leading Marks, developed the precursor to the today’s Boss Buddy as an application solution at Benton Foundry during the early 2000s. Traditional embossing, as was being done at Benton, required a male and female die to create the embossed effect on thin gauge materials, often resulting in tearing of the material and inconsistent quality.

Fast forward to 2014 and Laurie ran into a similar application problem as the one that she had solved over a decade prior, at Benton. So that began the official creation of Boss Buddy. The inception of the Boss Buddy stemmed from a need to overcome the challenges that Benton had experienced, and dictated introducing a new method that utilizes a female urethane mating piece instead of both dies. This innovative approach not only reduced material waste but also ensured a more consistent quality of embossed characters on metal tapes, such as the foil or stainless tapes available for use with the today’s Boss Buddy.

Unlike the typical wheel system that embosses one character at a time, today’s Boss Buddy employs impact presses that emboss a complete set of characters at once. This method allows for the inclusion of custom characters and longer numbers, offering a solution that is both faster and more consistent. The Boss Buddy’s adaptability extends to accommodating different types of metal tapes, catering to a wider range of industry needs.

Laurie’s expertise in the marking industry played a crucial role in the development of the Boss Buddy, a manual system designed to emboss foil labels used commonly for pattern ID. This system addresses the industry’s challenges head-on, providing a solution that leverages traditional components to replace outdated technology. The automation aspect of the Boss Buddy Plus signifies a notable advancement in the foundry sector, where efficiency and reliability are paramount.

The continuing story of the Boss Buddy is also one of collaboration and technical support. In the fall of 2023, Jason Karcher of Benton Foundry reached out to Laurie for assistance with some of the components on the original design solution at the plant that were not functioning optimally. Actually, it’s quite a testament to a design that had been in constant service for 20 years.

According to Jason Karcher, Tooling Department Manager at Benton Foundry, “There are few options for applying traceability for certified parts so it’s essential that this unit remains operational for our process and pattern labeling. The unit was not operating correctly and some “band aids” were used until Laurie visited and discussed the replacement parts and shared schematics.”

Laurie proposed to replace some press parts and introduce new steel type characters, along with arranging for a spare energy section for hot swaps. This exemplifies the ongoing commitment to streamlining maintenance allowing a quick return to operation and customer service at Leading Marks.

Karcher continues the story, “When the parts arrived, the unit was put back into first-class operation very quickly. It was a simple repair. I spent some time pulling the machine apart. Then replaced the items that have worn over the 20-ish years in service. Surprisingly, it wasn’t in all that bad of shape. The replacement parts fit as expected! The Machine runs well. More importantly, I have a greater peace of mind knowing I have replacement parts in house in the event something breaks.”

“All-in-all the process of ordering, replacing, and stocking the replacement parts/springs and do-dads went very well. I really appreciate Laurie’s advice and help on this machine. Her years of knowledge and experience are unmatched. I expect it to run problem-free in the back ground for some time.” said Karcher.

The Boss Buddy exemplifies how addressing specific challenges through innovation can lead to advancements that benefit the entire sector. Benton Foundry’s history, marked by consistent growth and strategic investments, provides the perfect backdrop for the development of such a transformative solution. The Boss Buddy is not just a product; it’s a symbol of progress in the foundry industry, showcasing how traditional processes can be reimagined for greater efficiency and reliability.

As the foundry sector continues to evolve, the Boss Buddy stands as a prime example of how innovative solutions can drive industry-wide change. Its development process, from conception to implementation, underscores the importance of expertise, collaboration and a deep understanding of industry challenges. The success of the Boss Buddy and its impact on Benton Foundry’s operations, highlight the potential for similar innovations to shape the future of manufacturing and industrial processes, ensuing sustainability and growth in an ever-changing technological landscape.

Benton Foundry’s recent core-making expansion further reflects Benton’s long-standing philosophy of reinvestment and modernization, a practice initiated by Fritz Hall in the 1970s and continued today under the leadership of his son, Jeff Hall. The approach has been to focus on smart, incremental growth through five –year capital expenditure plans, now in their ninth iteration. This strategy has seen Benton transform from a modest operation to a highly efficient, modern facility.

A

nearly $1 million dollar project to restore a reproducing population of freshwater mussels into the upper reaches of the West Branch of the Susquehanna River is scheduled to begin soon, by the Chesapeake Bay Watershed.

A National Fish and Wildlife Foundation Chesapeake Watershed Investment for Landscape Defense grant of $411,500 has been awarded to the Western Pennsylvania Conservancy to help fund the project in the river upstream from the dam at Lock Haven.

Matching funds from project partners of $566,400 brings the total project cost to $977,900.

The grant will enable the partners to take a comprehensive approach to mussel and river restoration through research, education and community outreach, the Pennsylvania Fish and Boat Commission says.

Partners besides the Commission include the Maryland Department of Natural Resources, Commonwealth University at Lock Haven and the Susquehanna River Basin Commission.

While mussels are plentiful in the West Branch from Lock Haven to the river’s confluence with the North Branch at Sunbury, they are absent upstream of the dam, the Commission points out.

“Freshwater mussel communities are absolutely essential to healthy rivers and streams and these restoration efforts are critical,” state malacologist Nevin Welte said. “This project is an incredible opportunity to make a difference in the West Branch Susquehanna River with each partner bringing a unique expertise to the table.”

The funding will allow thousands of mussels to be stocked and monitored over the next three years, said Zach Taylor, freshwater mussel propagation biologist with the Maryland DNR.

The funding will allow thousands of mussels to be stocked and monitored over the next three years, said Zach Taylor, freshwater mussel propagation biologist with the Maryland DNR.

The goal is to restore a reproducing population by creating multiple mussel beds in areas where the habitat is good, he said.

Some survey work to locate those sites has been done, Jordan Allison, a state fishery biologist said.

Historically, the West Branch watershed contained a thriving mussel community before the introduction of pollution associated with extensive coal mining and logging from the early 1800s through the early 1900s, Welte said.

Due to enhanced regulation of these industries and conservation efforts by natural resources agencies and their partners, great strides have been made in treating legacy sources of pollution, he said.

As a part of the project, eels will be transported from below the Conewago Dam in Maryland because they are among the travel hosts for mussels, Allison said.

Before being placed in the river upstream from the Lock Haven dam, the eels will be inoculated with baby mussels taken from the river in the Williamsport-Jersey Shore area and Pine Creek, he said.

The hope is when the mussels grow and drop off the eels they will create their own population, he said.

About 10,000 Pennsylvania-bred bay mussels will come from the Joseph Manning Fish Hatchery in Maryland of which Taylor is the freshwater mussel manager.

Welte provided this information about freshwater mussels:

- They provide multiple benefits to their surrounding ecosystems but are among the most imperiled groups of native animals in North America.

- A single mussel can filter up to three gallons of water per day, which is significant to water quality considering tens of thousands of mussels can live in a single mile of river.

- Mussels are also an important food source for native fish and other animals including muskrats, otters and raccoons.

Freshwater mussel populations continue to decline due to habitat loss, pollution and the introduction of invasive species. Of the 53 species of freshwater mussels that remain in Pennsylvania, 11 are listed as threatened or endangered.

There will be opportunities for the public to assist with the project through environmental days at the Lock Haven campus, the dates of which will be announced later, the commission says.

John Beauge

For PennLive

Congratulations to Chris Newhart (above), Benton Foundry’s 1st Shift Employee of the Quarter. Chris has worked at the Foundry since 2011. Chris works in our Molding Department as the Large Disa Operator. Chris was nominated for his low scrap rate (his molding related defects continue to be among the lowest in the department). Chris lives in Glen Lyon, with his wife, Cynthia, who also works at Benton Foundry. He enjoys hanging out with Cynthia and playing video games on the weekends.

Good Job!

Congratulations to Stefany Torrealba (below), Benton Foundry’s 2nd shift Employee of the Quarter. Stefany has been employed at the Foundry since 2022. She works in our Grinding Department as a Cleaning Machine Operator. She is also currently training for the Melt Department. She was nominated by multiple supervisors as she is a good worker and enjoys learning new responsibilities. Stefany lives in Muncy and she enjoys listening to music, watching movies, cooking and going to the gym in her spare time.

Congratulations!

A

sk a foundry worker what they do and they might humbly say that they “melt metal and pour it into a mold to make a casting”… More eloquently stated:

“I am feeding and clothing the people of the world. I am purifying and transporting the water that you drink. I am digging the world’s coal and drilling its oil. I am building thousands of miles of highways and railroads, and the locomotives, trucks, and automobiles that travel over them. I make the airplanes that fly through the air, and the ships that sail the seven seas. I make the tools with which individuals accomplish their work and I sadly admit that I make the implements of war with which mankind uses to fight with. Products of a foundry are in the hospital delivery room where you were born, in your home where you live and on the work bench where you work, and in the mortuary when you die. Throughout life, I have bettered your standard of living to a point where the working today live in a splendor undreamed by the kings of the middle ages. I have put astronauts into orbit around the Earth and I have sent them to the Moon and back. In the process of all these accomplishments, I have made a positive impact on the world’s environment by recycling waste and transforming it into useful products.”

“I am feeding and clothing the people of the world. I am purifying and transporting the water that you drink. I am digging the world’s coal and drilling its oil. I am building thousands of miles of highways and railroads, and the locomotives, trucks, and automobiles that travel over them. I make the airplanes that fly through the air, and the ships that sail the seven seas. I make the tools with which individuals accomplish their work and I sadly admit that I make the implements of war with which mankind uses to fight with. Products of a foundry are in the hospital delivery room where you were born, in your home where you live and on the work bench where you work, and in the mortuary when you die. Throughout life, I have bettered your standard of living to a point where the working today live in a splendor undreamed by the kings of the middle ages. I have put astronauts into orbit around the Earth and I have sent them to the Moon and back. In the process of all these accomplishments, I have made a positive impact on the world’s environment by recycling waste and transforming it into useful products.”

It is no wonder that – “I am proud to be a foundry worker!”

This message was paraphrased and expanded from a letter displayed in the lobby of Galesburg Castings, Galesburg, Illinois

OSHA revealed the top 10 safety violations at the NSC (National Safety Council) Safety Congress & Expo. The Occupational Safety and Health Administration announced its most frequently cited workplace safety standards for the fiscal year 2023. Eric Harbin, OSHA Region 6 administrator, presented the preliminary data for “OSHA’s Top 10” during the 2023 NSC Safety Congress & Expo.

Fall Protection – General Requirements remain at the top of the list for the 13th year in a row, followed by Hazard Communication and Ladders.

“Although incredible advancements are made in safety each year, we continue to see many of the same types of violations appear on OSHA’s Top 10 list,” said Lorraine Martin, NSC president and CEO. “As a safety community, we must come together to acknowledge these persistent trends and identify solutions to better protect workers..”

The Top 10 most frequently cited workplace safety standards for FY 2023, which ended Sept. 30, are:

- Fall Protection—General Requirements (1926.501):7,271 violations

- Hazard Communication (1910.1200):3,213

- Ladders (1926.1053):2,978

- Scaffolding (1926.451):2,859

- Powered Industrial Trucks (1910.178):2,560

- Lockout/Tag-out (1910.147):2,554

- Respiratory Protection (1910.134):2,481

- Fall Protection – Training Requirements (1926.503):2,112

- Person Protective and Lifesaving Equipment – Eye and Face Protection (1926.102):2,074

- Machine Guarding (1910.212):1,644

FSM Magazine

December 2023

David Straub – Highest Molding Efficiency

Ed Evans – Lowest Scrap Rate Molding

Luis Cruz & Jacqueline Artero – Highest Foxall Grinding Uptime

Jesus Martinez & Jesus Pina – Highest Grinding Efficiency

Glenda Briones – Highest Core Machine Operator Efficiency

Myriam Mayorga – Highest Core Assembly Efficiency

- 33% of Americans say spring is their favorite season.

- The first day of spring is known as the vernal equinox.

- In Latin, the word vernal means “spring” and equinox means “equal night.”

- In the North Pole, the spring equinox marks the start of six months of uninterrupted daylight.

- Whereas in the South Pole, the spring equinox marks the start of six months of darkness.

- Studies show that babies born in the spring are more likely to be night owls and optimistic.

petal talk®

Ed Posluszny

Cynthia Newhart

Jervin Barrientos

John Hospodar

Cheryl Brown

Cody Snyder

Bo Boston

Joe Vanderlick

Travis Hayman

Lynn Miller

Chad Davis

Sam Salmeron

Matt Kittle

Sabina Lopez

Rob Smith

David Emmett

Crystal Applegate

Glenn Cregar

Jackie Showers

Sheila Vansock

Nick Wilson

Sean Burke

Bob Houser

Xenia Ponce

Colin Jandrasitz

Boyd Lore

Morgan Hoover

John Harvey

Irving Wolfe

Dave Eveland

Jordan Winn

Allan Rodriguez

Joy Wolfe

Cody Bown

Juan Ponce

Jeffril Romero

Jose Mendoza

Frank Packer

Albert Phillips

Matt Herr

Roxi Ortiz

Steven Saxe

Ben Gonzalez

Don Copeland

Concepcion Martinez

Bobby Campbell

Elizabeth Strauch

Theresa Kubasek

Tamara Mabus

Jhonatan Bernal

Brittan Kittle

William Ferguson

Jose Lopez

Tim M. Schechterly

Amanda Carrasquillo

Bill Ferguson Jr.

Didimo Gamboa

Kevin Trychta

Duane Eshleman

Sergio Aguilera

Rob Bowman

Jim Lechleitner

Deb Clocker

Douglas Perez

Mike Parsons

Martha Pineda

In what year did we publish our first Meltminder Newsletter?

Answer will be in 2nd Quarter 2024

Answer from 4th Quarter question: Who were our top five customers in 1975?

Taco Pump, Marlow Pump, Garden Way, Howell Electric and Westinghouse

Congratulations to Brian Bedosky for being in the top five AFS (e-learning) students in the month of February.

Thanks to the Production Office for doing a great job in Tamara’s absence.

Good Job to both the Melt Department and Maintenancecrews for a very smooth preplanned coil change on furnace 4.

Congratulations to Yesslan Ruiz for completing her automatic molding training. She has been a solid addition to our molding team.

Awesome Job to Jeffril Navas or learning furnace operations.

Good Job to Tim Schechterly and Kyle Hall for the work they have done on the muller/sand system which has led to a noticeable improvement in sand consistency.

Congratulations to Tim Shepherd on becoming the second shift Molding Supervisor, from the assistant supervisor.

Awesome Job to Cody Bown for completion of his ABB Training IRC5 Programming.

Congratulations to Dave Buma for earning his Universal HVAC Technician Certification.

Good Job to Ed Gill and Nate Steinruck for completion of the OSHA 30 training.

Congratulations to Jim Tumolo – he is now the second shift Core Room Supervisor.

Awesome Job to Isabella Kubasek for pursuing new endeavors in the Quality Lab.

Good Job to everyone taking the ESL (English as a second language) courses.

Thank you goes out to Steve Saxe, Greg Vandine, Matt Kittle, Jeff Jones and Wilberth Lopez for helping with maintenance needs.

A thank you to all employees that have been completing tasks outside their normal duties, helping with the pattern shop and maintenance needs.

Congratulations to Sean Burke for recently obtaining the rank of E7 (Sergeant First Class) in the Army National Guard at Indian Town Gap.

Awesome Job!

“When the government fears the People, that is liberty – When the People fear the Government, that is tyranny.”

~Thomas Jefferson